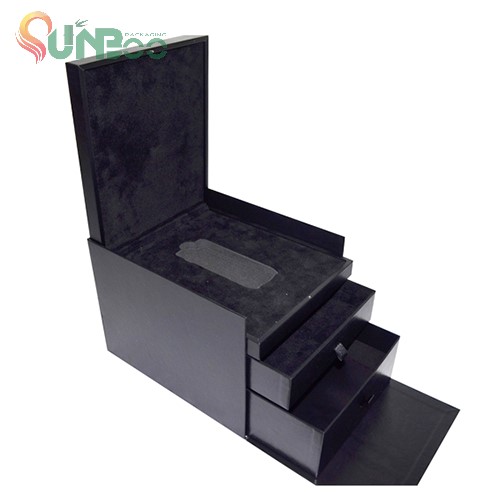

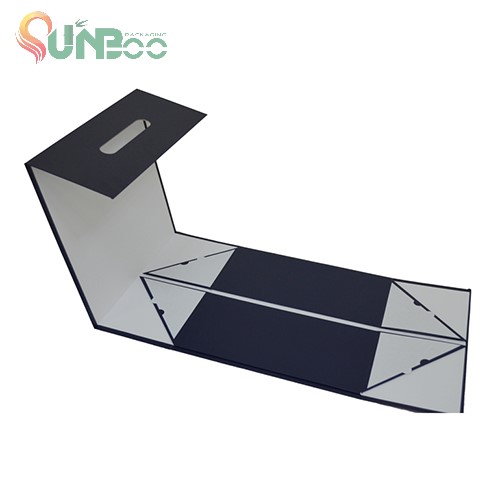

Black Collapsible Rigid Boxes With Tape And Magnetics

Black Magnetic Foldable Box is made of rigid hard cardboard. Rigid cardboard Packaging box is widely used in high end market which uses sturdy cardboard with different external paper or internal paper to make the box very different with corrugated box or folding cartons.

- SUNBOO

- CHINA

- 20 days around

- 150,000 pcs per month

- E- catalog.pdf

Details

The demand for rigid boxes is rapidly increasing among brands because of their stylish designs and intelligent structure. As a result, elegant-looking collapsible boxes have become the first choice for businesses, especially those selling cosmetics, makeup, perfumes, or jewelry.

| All information of Bags and Boxes | |

| Size of items: | Customized sizes(Length x Width x Height)cm |

| Materials: | Coated 1 side paper: 170gsm | 190gsm | 210gsm | 230gsm | 250gsm | 300gsm |

| Coated 2 sides paper: 128gsm | 157gsm | 180gsm | 220gsm | 250gsm | 300gsm | |

| Grey Cardoboard = 600gsm | 800gsm | 1000gsm | 1200gsm | 1400gsm | 1800gsm | |

| Color printing: | Offset | Flexo | Silk printing for PMS or CMYK |

| Surface Finishing: | Matt/Glossy lamination | Varnishing | Aqueous coating | Flocking | Gold/Silver hot stamping |

| | Debossed/Embossed | Texture | Spot UV | |

| Accessories: | Bags = Silk Ribbons | Grosgrain Ribbons | PP/Cotton handles | Plastic end | Eyelets |

| Boxes = Ribbons | PVC/PET tray | EVA | Sponge | Velvet | Cardboard | Flocking inserts | |

| Artwork Format: | AI | PDF | CDR |

| Custom Designs: | Bags = Hand-made paper bag | Twisted paper handles bag |

| Rigid boxes | Perfume Boxes | Foldable Boxes | Cosmetic Boxes | Wine Boxes | Chocolate | |

| Boxes | Watch Boxes | Round Boxes | Book Shape Boxes | |

| Sampleing Time: | 7 Days |

| Lead time: | 20-30 Days |

These boxes come in different shapes and sizes to meet the requirements for all sorts of products. sunboo packaging is a packaging company offering high-quality custom rigid boxes

Rigid Box Types

There are two types of such boxes. The types include partial finish and full finish.

1. Partial Finish

Partial finish boxes only cover the exterior of the box. As a result, the chipboard inside is visible. No additional outer layer is there. Also, it keeps the Kraft or grey chipboard material in view. So, it is not fully complete. There is only partial completion.

Single pieces of chipboard make them up. They have pierced creases for folding.

The wrapping is only for the inner edge finishing of the cases. Also, they are easy to make. Hence, few materials are required. They save time to produce and give better output.

2. Full Finish

In the full finish, no chipboard is visible. The rigid product is in total covering. There are 2-3 millimeters of thickness in the chipboard. It is better than a partial finish. Each side of the box has a different piece of chipboard. Various finishing options are available as needed. Additionally, these cases also have a wrap around them. It can be default white or printed.

Tags

Get the latest price? We will reply as soon as possible (within 12 hours)