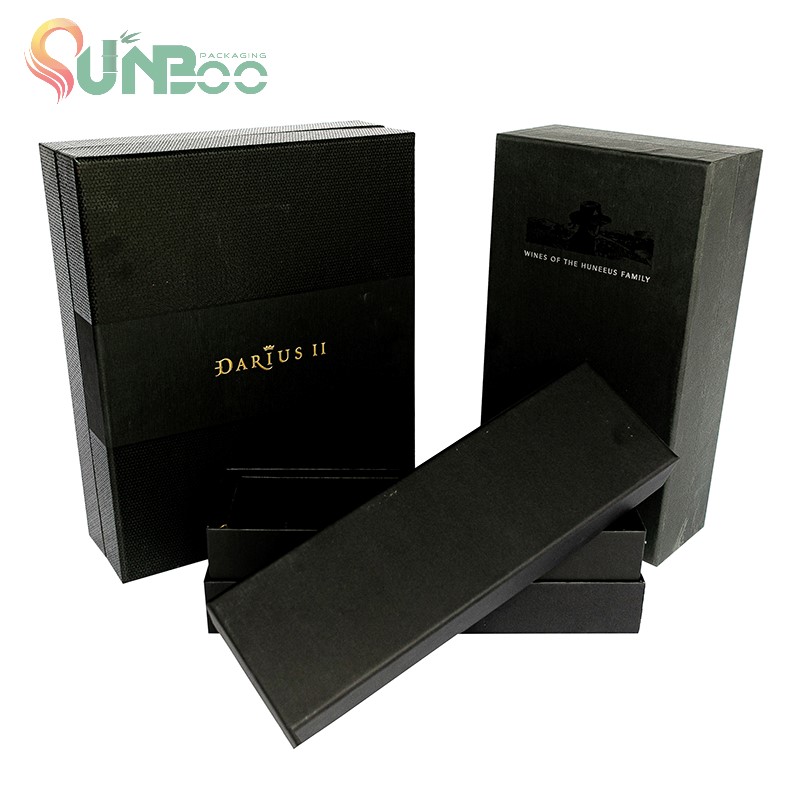

Luxury Wine Box Red Wine Box For Gift

Getting your wine prepared for transport is extremely important when it comes to moving a collection between geographical locations.

A professional wine moving company should always be your go-to solution for proper wine shipping boxes and packaging.

- SUNBOO

- CHINA

- 20 days around

- 150,000 pcs per month

- E- catalog.pdf

Details

Why customize your wine packaging boxes?

1. Enhance your Brand: to personalize your own wine logo boxes is huge value for your brand promoting. Each time customer buy your wine, they will be reminded by your logo printed on the wine boxes. And when you choose one of the color to your unique color, that color can be a symbolize. When people see that color, they will think of your brand. In this way you can save a large amount of money that spent on the advertisement.

Enhance your Brand

2. For Displaying: when you are intend to open a ceremony or anniversary in your company to promote your sales or introduce a new product, some quantity of special wine displaying boxes will be much helpful to achieve your purpose. The participants will be moved of your creation for the wine packaging, in the same time, will pay special regard to your new brand wine.

For Displaying

3. Protecting: When you customize your own wine packaging boxes, that means you will customize the size, color as well as the inserts. With the perfect size and insert, you no need to worry the wine bottles or glasses inside will be broken, even during the shipping time. And you can also custom the suit wine bags to pack your own wine boxes, your customer will appreciate very much of you.

| All information of Bags and Boxes | |

| Size of items: | Customized sizes(Length x Width x Height)cm |

| Materials: | Coated 1 side paper: 170gsm | 190gsm | 210gsm | 230gsm | 250gsm | 300gsm |

| Coated 2 sides paper: 128gsm | 157gsm | 180gsm | 220gsm | 250gsm | 300gsm | |

| Grey Cardoboard = 600gsm | 800gsm | 1000gsm | 1200gsm | 1400gsm | 1800gsm | |

| Color printing: | Offset | Flexo | Silk printing for PMS or CMYK |

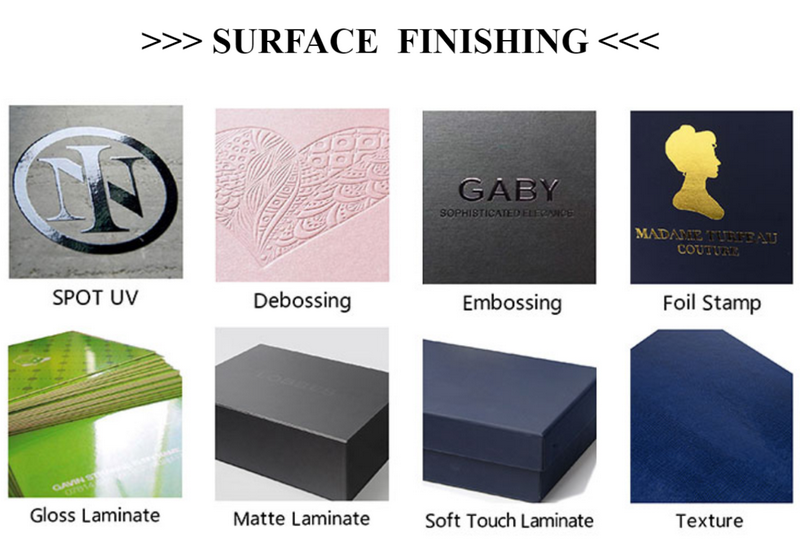

| Surface Finishing: | Matt/Glossy lamination | Varnishing | Aqueous coating | Flocking | Gold/Silver hot stamping |

| | Debossed/Embossed | Texture | Spot UV | |

| Accessories: | Bags = Silk Ribbons | Grosgrain Ribbons | PP/Cotton handles | Plastic end | Eyelets |

| Boxes = Ribbons | PVC/PET tray | EVA | Sponge | Velvet | Cardboard | Flocking inserts | |

| Artwork Format: | AI | PDF | CDR |

| Custom Designs: | Bags = Hand-made paper bag | Twisted paper handles bag |

| Rigid boxes | Perfume Boxes | Foldable Boxes | Cosmetic Boxes | Wine Boxes | Chocolate | |

| Boxes | Watch Boxes | Round Boxes | Book Shape Boxes | |

| Sampleing Time: | 7 Days |

| Lead time: | 20-30 Days |

Our luxury wine box are perfectly designed boxes ensure that your gift stands out during holidays, bridal shower, weddings, birthdays or any other gift giving occasion.

Wine box for gift packing with elegant and easy way to wrap a special bottle of wine or champagne and our wine boxes are durable enough to be reused

The treatment process of the box surface:

1. Laminating

The advantages of the film are waterproof, storage-resistant, and beautiful. Laminating glue refers to a kind of glue that combines bopp film on paper. At present, there are two ways of touching printed packaging products in China, one is water-based laminating and oil-based laminating, and now water-based laminating is the main method. , The water-based coating method is based on the concept of environmental protection, and its effect is slightly worse than that of oil-based coatings.

Packaging box manufacturers' packaging printed materials are also divided into two types due to materials:

1. Glossy film (bright film), the bright film itself is relatively bright, and the surface of the box is shiny after being covered with the bright film.

2. Matte film, the matte film is a foggy surface; after the film is covered, the matte surface is like a matte frost.

2, bronzing

At present, the hot stamping method of the packaging box is anodized aluminum hot stamping foil, which mainly uses heating and pressure to transfer the text of the copy box to the surface of the hot stamped printed packaging paper. The colors are gold, silver, green, blue, and laser. etc. are called bronzing.

Hot stamping is characterized by clear patterns, beautiful appearance, bright colors, wear resistance, etc. In the printing of cigarette packs, the application of hot stamping technology accounts for more than 85%, and it is also widely used in the production of commercial packaging. It can be used as the finishing touch, highlighting the theme, showing dignity, etc., especially for trademarks, logos, company names and other places that need to be highlighted.

3, hit the bump

Embossing is an important process in the post-press process of packaging, and it is an embossing method that does not use printing ink. When embossing, a set of concave and convex templates corresponding to the Yin and Yang of the graphics and texts is used, and the substrate is placed between them, and the embossed concave-convex graphics and texts are pressed out by applying a large pressure. This method is mostly used for post-press processing of printed matter and packaging boxes, such as for decoration of packaging boxes, trademarks, cigarette packs, New Year cards, bottle labels, etc., so that it can obtain a vivid and beautiful three-dimensional effect. Proper use of embossing process can increase the layering of printed patterns and play a finishing touch on packaging products. This process has the lowest cost in post-press surface treatment.

4. UV scrub

UV frosting is a post-press process that dries and cures ink by ultraviolet light. It requires the cooperation of UV ink containing photosensitizer and UV curing lamp. The UV process transfers the pattern and text to the surface of the UV printed packaging paper. Make it bright and special, especially for local printing parts such as trademarks, logos, and company names.

Tags

Get the latest price? We will reply as soon as possible (within 12 hours)