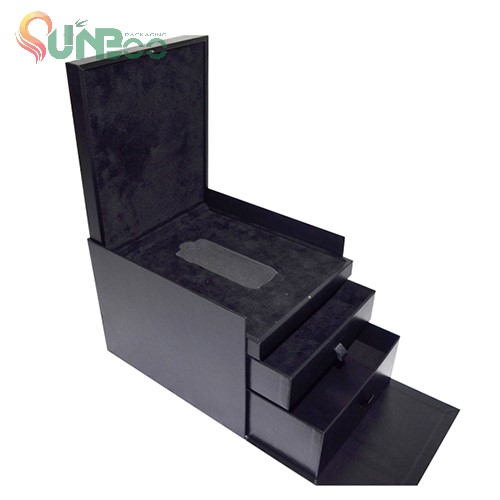

Magnetic Rigid Box With White Ribbon In Grey Color

Eco-friendly rigid packaging can stand to become one of the most sought-after packaging solutions. This popularity comes from the fact that it offers incredible durability and visual aesthetics.

- SUNBOO

- CHINA

- 20 days around

- 150,000 pcs per month

- E- catalog.pdf

Details

magnetic rigid box are a certain method to generate money if you operate a packaging firm. Using the best bespoke packaging solutions for luxury packaging will raise brand recognition and represent the purity of the product, improving the revenues and distinguishing your services. There are a variety of packaging solutions available, but nothing surpasses the gorgeous and elegant rigid boxes wholesale market.

| All information of Bags and Boxes | |

| Size of items: | Customized sizes(Length x Width x Height)cm |

| Materials: | Coated 1 side paper: 170gsm | 190gsm | 210gsm | 230gsm | 250gsm | 300gsm |

| Coated 2 sides paper: 128gsm | 157gsm | 180gsm | 220gsm | 250gsm | 300gsm | |

| Grey Cardoboard = 600gsm | 800gsm | 1000gsm | 1200gsm | 1400gsm | 1800gsm | |

| Color printing: | Offset | Flexo | Silk printing for PMS or CMYK |

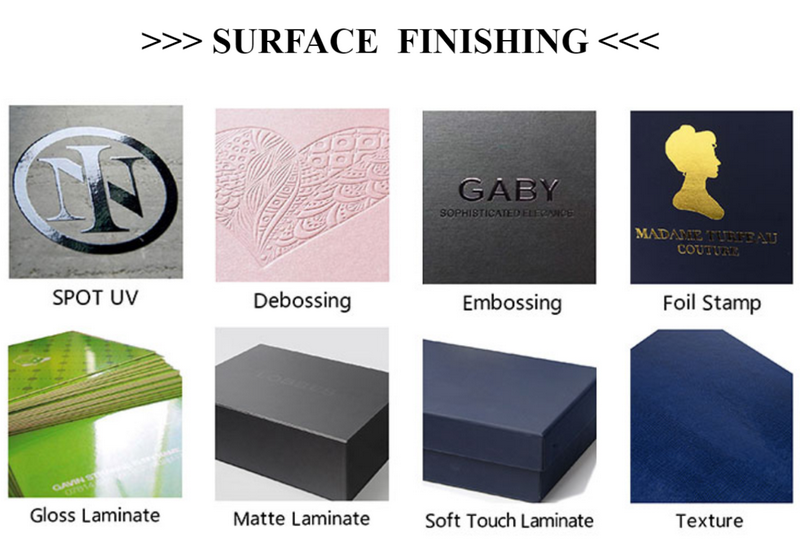

| Surface Finishing: | Matt/Glossy lamination | Varnishing | Aqueous coating | Flocking | Gold/Silver hot stamping |

| | Debossed/Embossed | Texture | Spot UV | |

| Accessories: | Bags = Silk Ribbons | Grosgrain Ribbons | PP/Cotton handles | Plastic end | Eyelets |

| Boxes = Ribbons | PVC/PET tray | EVA | Sponge | Velvet | Cardboard | Flocking inserts | |

| Artwork Format: | AI | PDF | CDR |

| Custom Designs: | Bags = Hand-made paper bag | Twisted paper handles bag |

| Rigid boxes | Perfume Boxes | Foldable Boxes | Cosmetic Boxes | Wine Boxes | Chocolate | |

| Boxes | Watch Boxes | Round Boxes | Book Shape Boxes | |

| Sampleing Time: | 7 Days |

| Lead time: | 20-30 Days |

Premium Quality Magnetic Rigid Boxes made with high-end raw material and using the latest technology to ensure edge to edge perfection. Using these high-tech tools, sunboo Packaging ensures perfect fitting, fine finishing, and countless customization options for bulk magnetic boxes orders. The best market price guaranteed by industry specialists.

The raw and auxiliary materials used in Magnetic Rigid Boxes not only have many varieties, but also have a wide range, and have higher quality requirements. The quality of the selected materials determines the quality of the product. Qualified raw and auxiliary materials are the ultimate guarantee of quality. Because of this, the selection of materials for each component of a complete Magnetic Rigid Boxes is the most important key.

Raw and auxiliary materials include:

1. Ribbon : woven from silk or cloth material, the width is generally 10mm--20mm, and the colors are various. It is mostly used for the decoration of gift boxes or the rope of bags.

2. Satin cloth: It is generally silk fabric, and the basic structure is plain weave. Silk fabrics also have ordinary weave fabrics such as twill weave and satin weave, and special crepe fabrics, velvet fabrics, and leno weave.

3. Velvet: After brushing, the surface of the cotton fabric is rich and fluffy. Through the pinhole velvet process on the surface of the cloth, more fluff is produced, with a strong three-dimensional effect, high gloss, and soft and thick to the touch.

4. Ring sponge: Wrap flannelette on the surface of the sponge, fold out several grooves, insert it into the box, and place rings and other items in the grooves.

5. Elastic rope: a kind of braided fabric, the outer surface is woven with silk fabric, the inner core is rubber band, and the shape is round, flat and other shapes.

6. Blister shell: a plastic extrusion processing product, the main principle is to heat the flat hard plastic sheet to soften it, then vacuum absorb it on the surface of the mold, and form it after cooling. It is generally used to fix the contents.

7. Flocking blister: a plastic extrusion processing product, the main principle is to heat the flat hard plastic sheet to soften it, then use vacuum to absorb it on the surface of the mold, and then shape it after cooling. Then stick a layer of velvet material on the surface of the plastic hard sheet, so that the surface has a velvet feel, which is used to improve the grade of the package, and is generally used for fixing the contents.

8. Magnets: Refers to objects or materials that have a magnetic field around and within themselves. Most of the gift boxes use circular magnets or strip magnets.

9. Iron sheet: the metal sheet used with the magnet, the size and thickness can be determined according to the demand.

10. PE bag: PE is the abbreviation of polyethylene, which is a thermoplastic resin obtained by polymerization of ethylene. In industry, it also includes copolymers of ethylene and a small amount of α-olefins. Mainly used to make film or PE flat bags, ziplock bags, etc.

11. PU leather: PU is polyurethane, and PU leather is the skin of polyurethane. It is a man-made synthetic material with the texture of real leather and is very strong and durable.

12. Rubber blank: use plastic materials, according to the requirements of the production process, cast into the required shape, and solve the processing problem of special-shaped boxes that cannot be completed by gray board or density board.

13. PVC: It is polyvinyl chloride, which is a material with a wide range of uses and is often used in our lives. Such as PVC pipe, PVC floor, PVC film base, etc., its film base is widely used in the fields of window stickers for packaging products.

14. PET: Polyethylene terephthalate, a high polymer. Ethylene terephthalate is obtained from the esterification of terephthalic acid and ethylene glycol. Its film base is widely used in window sticking, film covering and other fields of packaging products.

15. EVA: It is a common name we define. Its chemical name is ethylene-vinyl acetate copolymer. It is a material that is much harder than sponge. It has the characteristics of good flexibility, shockproof, anti-skid, and strong pressure resistance. It plays the role of fixing and protecting products in the gift box.

16. Styrofoam (EPS): Also called porous plastic. It is a plastic with numerous micropores inside made of resin as the main raw material. Light weight, heat insulation, sound absorption, shockproof, corrosion resistance. There are soft and hard points, widely used in the field of packaging.

17. Pearl cotton (EPE): It is composed of low-density polyethylene fat through physical foaming to produce countless independent bubbles. It overcomes the shortcomings of ordinary styrofoam that are fragile, deformed, and poor in recovery. It has many advantages such as water and moisture resistance, shock resistance, sound insulation, heat preservation, good plasticity, strong toughness, recycling, environmental protection, and strong impact resistance. It is an ideal material for traditional packaging.

18. Sponge: It is a porous material with good water absorption. Commonly used sponges are made of wood cellulose fibers or foamed plastic polymers. Gift boxes are mostly used for interior padding.

19. Jelly glue: Also known as jelly glue, the main component of jelly glue is animal protein, does not contain benzene and formaldehyde solvents, and is non-toxic and environmentally friendly. It will not pollute food and packaged items, and its advantages are no deformation, no mildew and foaming, and it can enhance the stiffness of paper products. In addition to strong viscosity, jelly glue also has moderate softness. In production application, its drying speed can be divided into: high speed, medium speed and low speed. It is widely used in papering of gift boxes, wine boxes and cosmetic boxes.

20. Bubble bag: Processed from low-density polyethylene, it is a transparent flexible packaging material commonly used at present. The principle is that the film contains air to form bubbles to prevent product impact and ensure that the product is protected when it is shaken. , At the same time, it also has the function of heat preservation and heat insulation. Since the middle layer of the air cushion film is filled with air, it is light in weight, full of elasticity, and has the properties of sound insulation, shockproof and wear resistance.

21. Gray cardboard: gray card for short, is produced from a kind of recycled waste paper. The products are divided into single gray, double gray, full gray and high gloss. It is an environmentally friendly packaging material. Quantity ranges from 250g to 10,000g, thickness ranges from 0.4mm to 20mm, and there is no upper limit for thickness and quantity. The main purpose of the product: packaging gift boxes, hardcover books, etc.

Tags

Get the latest price? We will reply as soon as possible (within 12 hours)