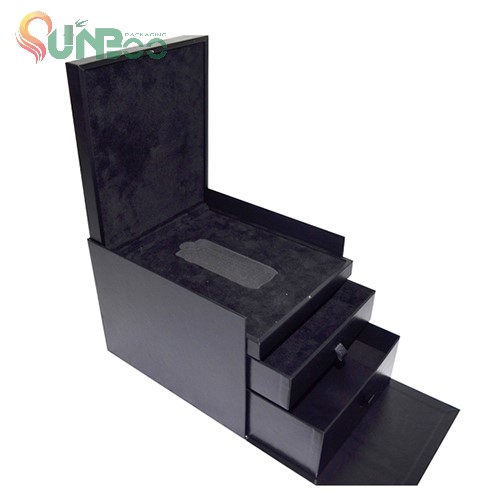

Small Rigid Drawer Box With Ribbon

Luxury rigid boxes are vital to the success of your goods since they provide your buyers with the first image of your product. The perceived worth of a product is directly proportionate to its packing. When your customers get packaging designed just for them, they’ll be thrilled and more inclined to spread the word about your brand.

- SUNBOO

- CHINA

- 20 days around

- 150,000 pcs per month

- E- catalog.pdf

Details

Rigid Box sunboo packaging is helping brands to get their beautiful drawer style rigid boxes manufacturer at very high quality with affordable prices. Most of the buyers would love buy drawer style box with a Ribbon. which means a wow creating factors is common in all product promotions right. So we suggest our customers to choose our drawer style rigid boxes for their product packaging. Quality is the most wanted requirement to packaging company, so we sunboo packaging is committed to give our best quality in all our packaging.

| All information of Bags and Boxes | |

| Size of items: | Customized sizes(Length x Width x Height)cm |

| Materials: | Coated 1 side paper: 170gsm | 190gsm | 210gsm | 230gsm | 250gsm | 300gsm |

| Coated 2 sides paper: 128gsm | 157gsm | 180gsm | 220gsm | 250gsm | 300gsm | |

| Grey Cardoboard = 600gsm | 800gsm | 1000gsm | 1200gsm | 1400gsm | 1800gsm | |

| Color printing: | Offset | Flexo | Silk printing for PMS or CMYK |

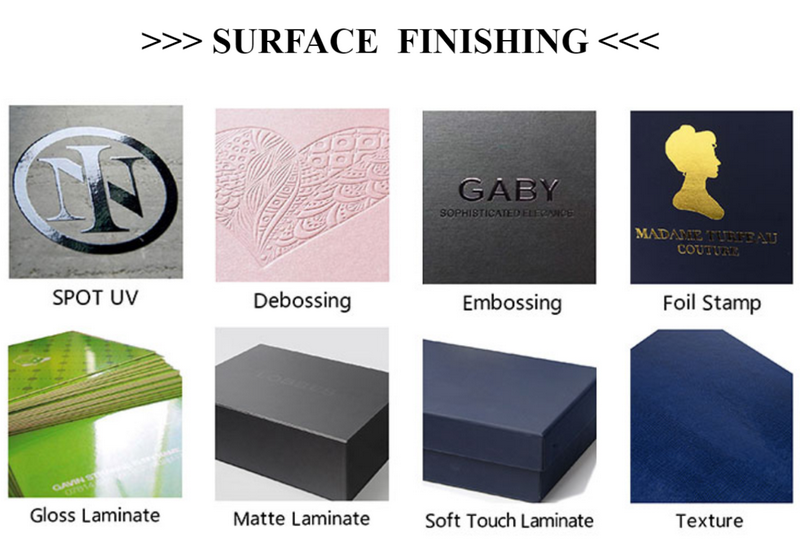

| Surface Finishing: | Matt/Glossy lamination | Varnishing | Aqueous coating | Flocking | Gold/Silver hot stamping |

| | Debossed/Embossed | Texture | Spot UV | |

| Accessories: | Bags = Silk Ribbons | Grosgrain Ribbons | PP/Cotton handles | Plastic end | Eyelets |

| Boxes = Ribbons | PVC/PET tray | EVA | Sponge | Velvet | Cardboard | Flocking inserts | |

| Artwork Format: | AI | PDF | CDR |

| Custom Designs: | Bags = Hand-made paper bag | Twisted paper handles bag |

| Rigid boxes | Perfume Boxes | Foldable Boxes | Cosmetic Boxes | Wine Boxes | Chocolate | |

| Boxes | Watch Boxes | Round Boxes | Book Shape Boxes | |

| Sampleing Time: | 7 Days |

| Lead time: | 20-30 Days |

sunboo packaging custom rigid box is the complete package. Made to protect and present your product and create a unique experience when it reaches you.

sunboo packaging have optimized its production and finishing techniques to provide a range of rigid box solutions from top-load, complex and composite boxes to slipcases, display packs and window boxes.

sunboo packaging bring expertise in production and finishing techniques

Commonly used processes for packaging materials

four color printing

1. The so-called four colors are: cyan (C), magenta (M), yellow (Y), black (K) four inks, all colors can be formed by mixing these four inks, and finally realize color graphics.

2. The most common and most common printing, the printing effect is different on different substrates.

spot color printing

1. Spot color printing means that a special ink is used to print the color during printing, which is more vivid than the color mixed by four colors. Commonly used are special gold and special silver.

2. There are many spot colors. Refer to the Pantone color card. Spot colors cannot achieve gradient printing. If necessary, add four-color printing.

clear glue

1. After printing, a transparent plastic film is applied to the surface of the printed matter by hot pressing to protect and increase the gloss. The surface is bright, as shown in the picture below.

2. The most basic process of carton surface treatment. There is also varnish similarly, but gluing can enhance the hardness and tensile properties of paper.

Dumb glue

1. After printing, a transparent plastic film is applied to the surface of the printed matter by hot pressing to protect and increase the gloss. The surface is matte, as shown in the picture below.

2. The most basic process of carton surface treatment, similar to varnish, but gluing can enhance the hardness and tensile properties of paper.

over UV

1. Partial glazing is applied to the prominent parts of the printed matter to make the partial pattern more three-dimensional.

2. Printed with matte glue process, there is no effect when glossy glue is used.

hot stamping

1. Hot stamping uses the principle of heat transfer to transfer the aluminum layer in anodized aluminum to the surface of the substrate to form a special metallic luster effect.

2. The printing materials include gold, silver, red, green, blue and other colors, but hot stamping can only be monochromatic, and there are many kinds of colors, but not all colors are available in the market.

Convex

1. Use a set of concave and convex templates corresponding to the yin and yang of the graphic, place the substrate between them, and press out the embossed concave-convex graphic by applying a large pressure.

2. Paper of various thicknesses is acceptable, but cardboard cannot be embossed.

Coding

1. The process of using the inkjet printer to print the logo (production date, shelf life, batch number, company logo, etc.) on the product.

2. It can print simple character patterns with greater flexibility.

Composite bag

1. Composite bags are suitable for vacuum packaging or general packaging of food, electronic products, chemicals, medicines, tea and other products.

2. The process and paper that can be made are basically the same, and can be screen printed, printed and hot stamped.

Blister

1. Blister is a transparent material, the main raw material is PVC, PE, or PET.

2. It can directly replace the paper to make the box, and can also be used to form a card.

3. It can be used to fix the product inside the package, which is called inside the blister.

4. It can be screen printed, printed, or hot stamped.

5. It can be printed on the machine, but the printing cost is relatively high, and silk screen printing is generally used for small-scale production.

OPP bag

1. The OPP bag is stretchable polypropylene, which is a kind of plastic, and it is actually a plastic bag.

2. Before packing the outer box, put the product in an OPP bag, which looks clean and hygienic.

3. There are PP plastic bags and PE plastic bags for different materials.

4. It has the characteristics of high transparency and brittleness, and can also print various patterns and punch holes according to customer needs.

EVA

1. The chemical name is ethylene-vinyl acetate copolymer. The finished product made of it has the characteristics of good flexibility, shockproof, non-slip and strong pressure resistance.

2. Used in packaging and inside to fix and protect products.

3. There are a variety of colors to choose from, and the surface can be flocked or wrapped in fleece to enhance the visual effect.

sponge

1. It is a porous material with good elasticity. The density of the holes is different, and the elasticity is different.

2. Used in packaging and inside to fix and protect products.

3. There are a variety of colors to choose from, which are generally used directly without superimposing crafts.

shrink bag

1. It is a transparent bag made of a material that is highly shrinkable when it reaches a certain temperature, and is used to protect the package.

2. It is only used to protect the packaging, no other crafts will be done.

Tags

Get the latest price? We will reply as soon as possible (within 12 hours)